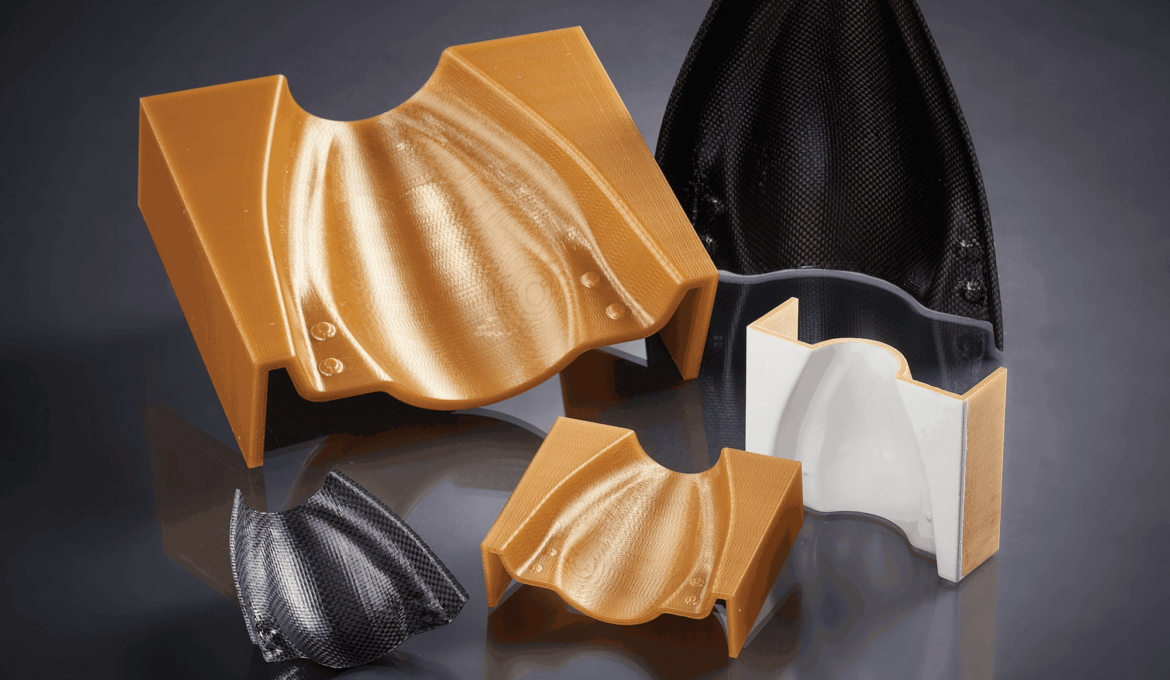

Ultem 1010, High-Strength, Heat Resistant Thermoplastic Material

A biocompatible, high-heat resistant engineering polymer. Ultem™ 1010 is used for specialist environments such as the aerospace or medical industries, where strength and heat resistance is vital.

This material is available in general purpose and certified grade resins for use in medical, health and food applications where sterilisation and biocompatibility may be required. Being one of the strongest FDM thermoplastics and a flight certified material, it’s able to withstand autoclave operations associated with composite tooling fabrication and often used in motorsport.

Key Features

Secondary Processes

Surface Treatments

Build Envelope

Build Resolution

Standard Colours

Material Properties

TENSILE STRENGTH, YIELD

64 MPa (XZ Axis) and 42 MPa (ZX Axis)

TENSILE MODULUS

2770 MPa (XZ Axis) and 2200 MPa (ZX Axis)

HDT

215 °C

IZOD IMPACT, NOTCHED

41 J/m (XZ Axis) and 24 J/m (ZX Axis)